Cases and custom foam inserts

How foam inserts enhanced product protection for a leading visual merchandising company

Background

In the fast-paced world of visual merchandising, precision and attention to detail are paramount. Our client, a highly regarded business with over two decades of experience, faced an urgent challenge. Tasked with delivering 250 bespoke packaging units for a high-profile product launch, they needed a manufacturer who could deliver quickly and without compromising on quality.

The challenge

The client required custom foam inserts that would:

- Protect the product: Ensuring the delicate items remained intact during transport

- Provide a premium presentation: Enhancing the product’s appeal with a high-quality finish

- Offer bespoke design and customisation: Tailored to fit perfectly within the packaging units

Given the tight lead times and high expectations, finding the right partner was crucial.

The solution

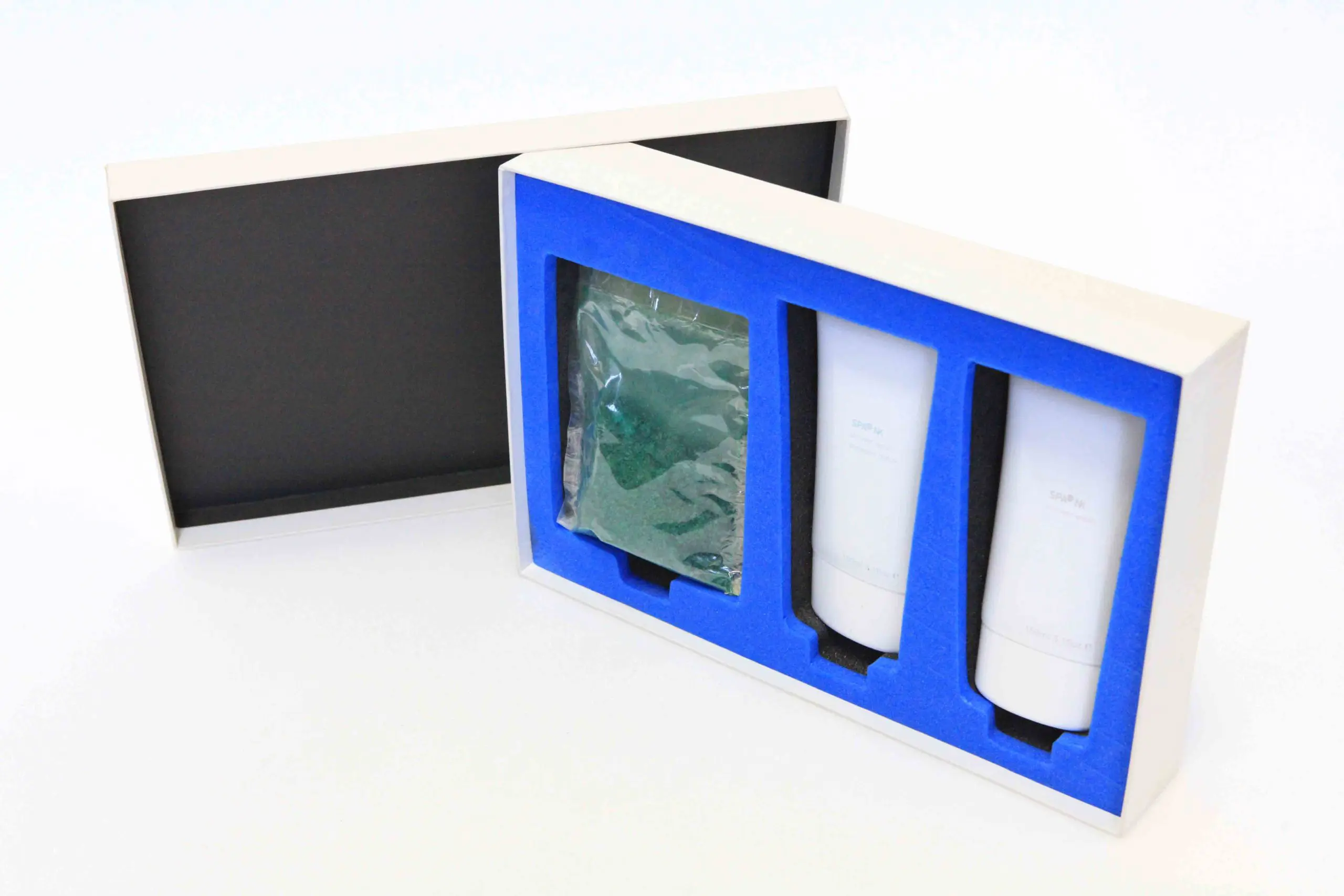

Kewell Converters stepped up to the challenge, leveraging their expertise in protective foam solutions. Within two weeks of the initial contact, two foam insert prototypes were designed and presented to the client. The selected materials included:

- Azote Foam: Known for its protective and aesthetic qualities

- Closed Cell Polyethylene Foam: Chosen in black to achieve a premium look

Key features

- Protective foam: Ensured the product remained secure and undamaged

- Bespoke design: Customised to fit the client’s specific requirements

- High-quality finish: Enhanced the product’s presentation, creating a ‘wow’ moment for the audience

The results

The collaboration led to flawless execution and impeccable design, meeting the client’s high standards. The quick turnaround, coupled with efficient and professional service, ensured the project’s success.

The client expressed their immense satisfaction with the project, stating:

“We specialise in the difficult and sometimes impossible – whether this is down to the incredibly tight lead times, or just the unusual nature of the enquiry. When we were tasked with creating bespoke packaging units for a high-end, product launch, we looked to outsource the custom foam parts. After contacting several foam converters to help us out, Kewell Converters were the only company to be unfazed by our request, the quantity required and the timescales. Following our first face-to-face meeting, it was clear they were the perfect partner. The whole team were responsive and wasted no time getting started. Each part we received was to the same high-quality finish as the first, and exactly as expected. The project was a big success and very well received by the client and recipients.”

Why choose Kewell Converters for custom foam inserts?

Kewell Converters design and manufacture bespoke foam inserts for numerous industries, also sourcing and supplying cases. We collaborate with premium case manufacturers to offer cost-efficient and practical casing solutions for Original Equipment Manufacturers (OEMs). Some of the renowned brands we work with include PELI Cases, MAX Cases, STORM Cases, and Rose Plastics.

Working with leading UK visual merchandising companies, we ensure that quality is paramount. Our dedication to detail and precision sets us apart, making us the preferred choice for complex and high-profile projects.

Explore our foam insert services

Protective foam inserts play a crucial role in product protection and presentation. Kewell Converters’ expertise in designing bespoke solutions ensures that even the most challenging projects are executed flawlessly. If you’re looking for a reliable partner to enhance your product protection, get in touch with Kewell Converters today.

Ready to enhance your product packaging with high-quality foam inserts? Contact our expert team now and discover how we can help you achieve impeccable results.

Read more on the blog case inserts and promotional and consumer packaging.