Masuri cricket helmets

Masuri and Kewell Converters: Redefining safety standards in cricket helmets

Enhancing safety and performance through innovative foam solutions

Masuri, a leading manufacturer of cricket helmets, faced the challenge of enhancing helmet safety and performance to meet stringent industry standards. Partnering with Kewell Converters, we developed foam components that significantly improved the durability and functionality of their Vision Series helmets. This collaboration resulted in helmets that not only met but exceeded existing safety standards, helping solidify Masuri’s position as a market leader.

Introduction

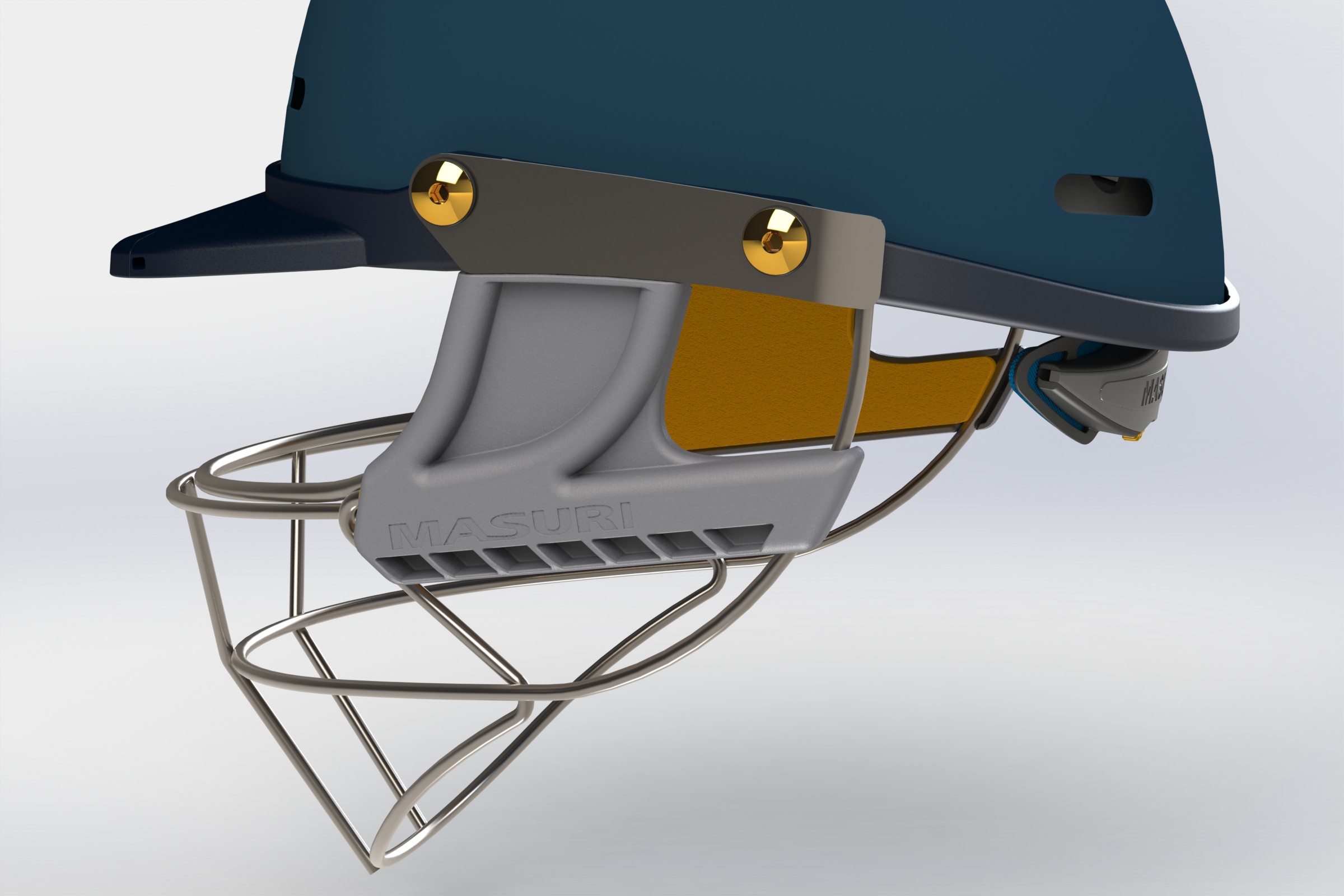

Masuri, based near Winchester, is renowned for producing the highest quality cricket helmets used by professional teams worldwide. Known for their lightweight design and unmatched comfort, Masuri helmets are meticulously crafted to ensure maximum safety for cricket players. The company invests heavily in research and development to explore innovative technologies, resulting in pioneering patents such as Active Peak Tech and Eyeline Grille. The Vision Series, strengthened by the Halo Reinforcement system, exemplifies Masuri’s commitment to excellence.

The problem

The International Cricket Council identified the need for further improvements in helmet safety, prompting Masuri to innovate. To achieve these stringent specifications, Masuri needed to develop advanced foam components that would enhance the durability and functionality of their helmets. This required substantial investment in research and development and collaboration with experts in material technology.

The foam solution

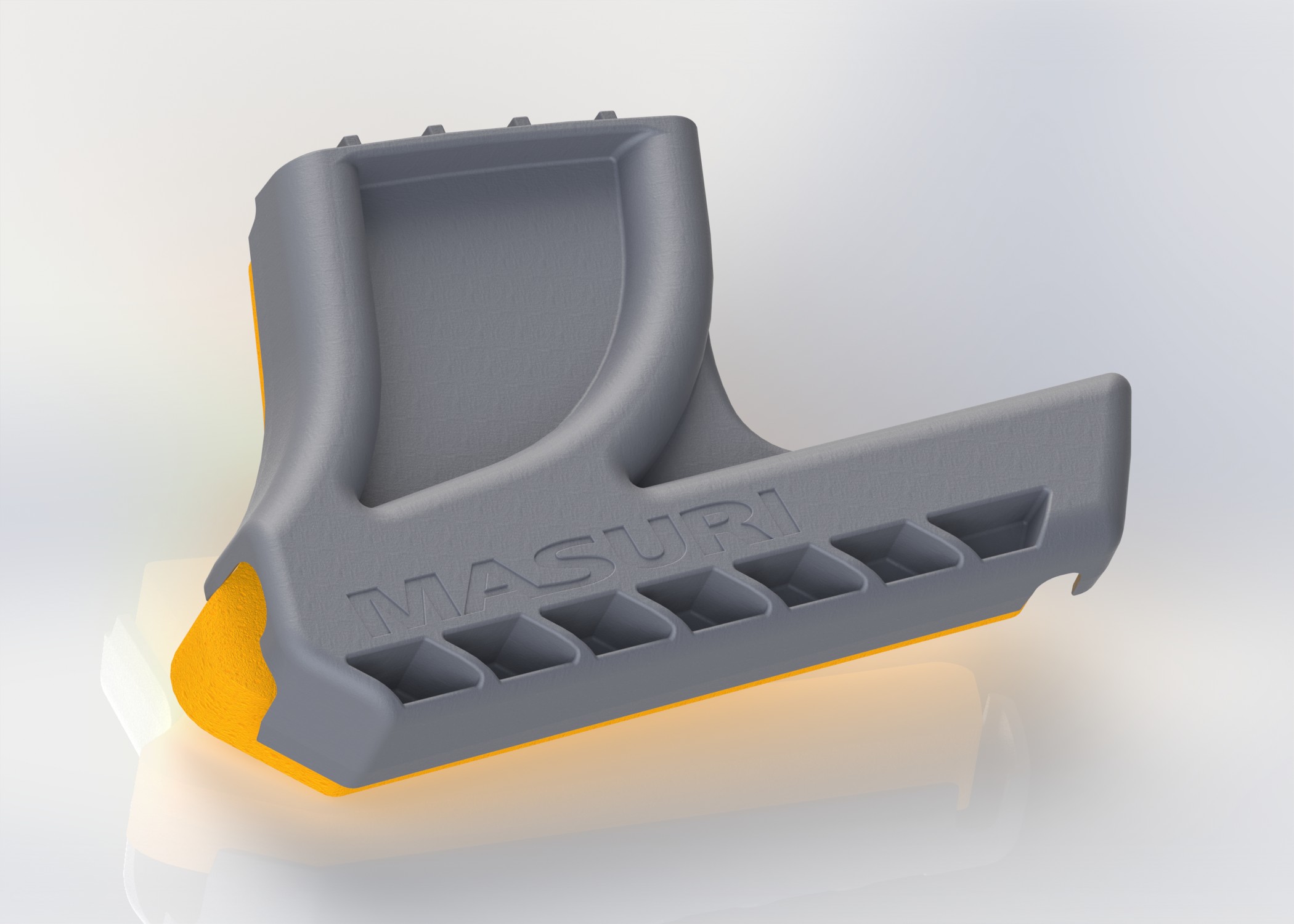

As specialists in the development and conversion of foam components, we were involved from the early stages of research and development, working closely with John Hardy, the former English cricketer. This collaboration led to the creation of trial foam components and prototypes tailored to the new Masuri Cricket Helmets.

The process involved numerous site meetings where carefully selected foam materials were reviewed and several iterations of designs and end parts were tested. We played a crucial role in finalising the foam polymer, grade, colour, and finish for production. Our expertise ensured that the final product met Masuri’s high standards for safety and performance.

Setting new standards

The collaboration between Masuri and Kewell Converters culminated in the development of the Masuri Vision Series helmets, which set new standards in the competitive cricket helmet market. The innovative design incorporated an articulated peak (Active Peak Tech) and a reinforced Eyeline Grille, effectively deflecting balls away from the player’s face. These features not only met the existing safety standards but exceeded them, establishing a new benchmark for cricket helmet safety.

The Vision Series received widespread acclaim for its superior safety and comfort. Masuri’s partnership with us enabled them to deliver a product that combined cutting-edge technology with practical design, ensuring the highest level of protection for players.

A manufacturing partnership that drove innovation

The successful collaboration between Masuri and Kewell Converters highlights the importance of manufacturing partnerships in driving innovation and achieving industry-leading results. By leveraging our expertise in foam technology, Masuri were able to overcome significant challenges and deliver a product that redefined safety standards in cricket helmets.

Learn more about who we work with and read more of our case studies.

Ready to elevate your product offerings with innovative foam solutions. Email our team now who would be delighted to help.