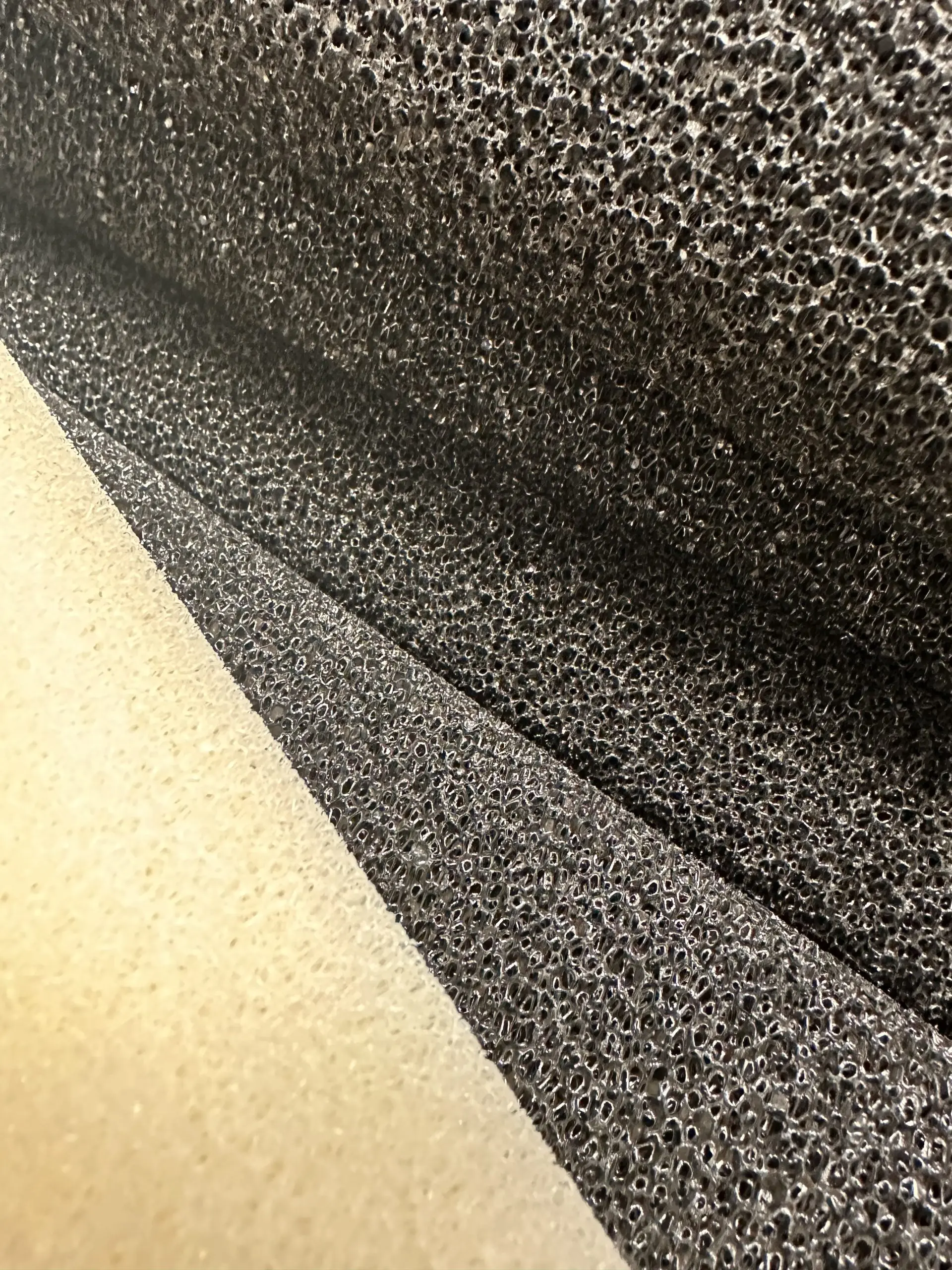

Air filter foam

Unravelling the superiority of our air filter foam

At Kewell Converters, our commitment extends beyond mere production. We are dedicated to supplying premium air filter foam, an indispensable component in HVAC systems and the automotive sector. Dive deep into the significance of this product and discover why quality is paramount.

Request a quote

HVAC systems & air filter foam

A harmonious connection

Purification essence

Air filter foam is pivotal in HVAC systems. Its primary function is to cleanse the air, trapping dust, pollen, and other contaminants, ensuring the distribution of purified air across a facility—crucial for safeguarding the well-being of occupants, especially in commercial spaces.

Efficiency & environmental responsibility

Incorporating superior foam can elevate HVAC system efficiency, curbing energy consumption. The result? Economical energy bills and a step towards environmental conservation.

Automotive precision

The role of air filter foam

Engine performance and durability: This foam stands as a guardian for automotive engines, keeping dust, dirt, and debris at bay. By doing so, it mitigates wear and tear on the engine’s components, maintaining optimal engine performance and prolonging its lifespan.

Smooth operations: Opting for our premium foam translates to reduced engine complications, ensuring seamless engine functionality.

Why opt for high-quality air filter foam?

Maximised efficiency: Superior foam offers enhanced airflow, optimising system efficiency. The outcome is tangible: minimised costs and slashed energy consumption across HVAC and automotive platforms.

Health & environment: Elevate indoor air quality by eradicating pollutants like dust, mould spores, and pollen. Plus, environmentally conscious choices reduce emissions, making the world a cleaner place.

System Longevity: Shield your systems from debris accumulation. Superior foam acts as a protective barrier, extending system life and diminishing frequent repair needs.

The downfall of compromising on quality

System underperformance: subpar foam might falter in efficient filtration, decreasing system productivity and escalating energy expenses.

Health concerns: compromising on foam quality can degrade indoor air quality, posing potential health risks.

Shortened lifespan & environmental hazards: inferior foam can hasten debris accumulation, curtailing system longevity and heightening pollutant emissions.

Making the right air filter foam choice

Factors to consider

Material: Filter foams come in diverse materials like polyurethane, polyester, and polyether. Match the foam type to your application’s unique demands.

Density & porosity: Balance between foam density and porosity, keeping in mind filtration efficiency versus airflow.

Chemical & temperature resilience: Opt for foam resilient to common chemicals and temperature variations in your domain.

Flame retardancy: Ensure your foam aligns with flame retardancy benchmarks, promoting safety and regulatory compliance.

FAQs

This foam ensures purified air distribution in HVAC systems and safeguards automotive engines from contaminants, directly impacting efficiency and longevity.

High-quality foam enhances system efficiency, resulting in reduced energy consumption and diminished emissions.

Subpar foam can reduce system efficiency, compromise indoor air quality, shorten system lifespan, and increase environmental pollutants.

It’s essential to balance between filtration efficiency and airflow. Consider your application’s specific requirements to make an informed decision.

At Kewell Converters, we emphasise delivering top-tier foam products tailored to the unique demands of our clientele. Your satisfaction and system efficiency are our top priorities.