From concept to retail reality: creating foam parts for the fashion and retail industry

How Kewell Converters’ high-performance closed cell foam parts enabled a seamless design for a sustainable fashion brand

Background

A new retail client Freitag specialising in upcycled bags approached Kewell Converters with an ambitious project. They needed foam parts to form part of the design for a new line of recycled bags made from a material containing recycled PET bottles in addition to discarded truck tarps and reflectors. Kewell Converters were tasked with manufacturing prototypes using high performance closed cell foam parts and fulfilling the order for this sustainable brand.

Challenge

The foam needed to integrate seamlessly into this sustainable design, as well as provide cushioning and comfort for the end user as a padded laptop compartment. The challenge was significant. Kewell Converters had to produce many customised foam parts within a 12-week timeframe.

On top of timing constraints, foam, although versatile, can be unpredictable, and issues such as blowholes can arise. However, Kewell Converters are highly skilled. Through stringent quality control measures, we have the expertise and know-how to work with a vast range of complex materials and the experience to recommend the right foam solution.

Solution

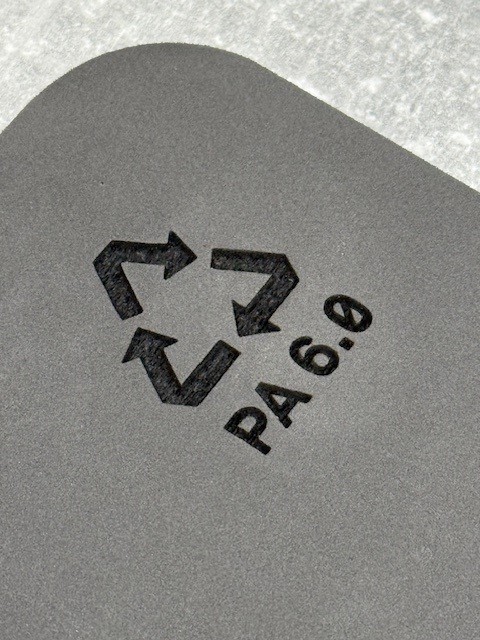

After initial discussions with foam manufacturer Zotefoams, Kewell Converters selected Zotek NB50 to make the foam parts. This is a high performance closed cell, cross-linked nylon foam that would integrate perfectly with a nylon bag for a retail brand to achieve consistency in the base product.

Kewell Converters had some of the required material in stock and got straight to work with the prototypes. Following approval of these, the engineering team started production and began fulfilling this order using the Hawkes NC40 die cutting press.

Results

The project was executed flawlessly, with zero rejected products and timely delivery. Impressed with the meticulous attention to detail and transparent communication, the client has subsequently selected Kewell Converters as their preferred partner for another project as well as recommending us to another company. By overcoming unique challenges with expertise and clear communication, Kewell Converters has proven to be a trustworthy and skilled partner for complex foam projects.

For more information on how Kewell Converters can support your retail or manufacturing needs with versatile foam solutions, visit enquiries@kewell-converters.co.uk

Read more case studies from Kewell Converters to understand how we work with different brands including a luxury sustainable fashion brand and creating an exquisite bespoke jewellery insert.

PHOTO CREDITS - Bildlegende