Composites

Engineered for excellence in material performance

Composite foam is a synthesised material engineered to offer a remarkable blend of strength, durability, and versatility. Specifically designed to meet the demanding requirements of multiple industries, our composites set new benchmarks for performance, reliability, and adaptability.

Request a quote

Key features

High strength-to-weight ratio: Exceptional load-bearing capabilities without compromising on weight.

Corrosion resistance: Ideal for environments that require long-lasting materials resistant to wear and tear.

Thermal and electrical insulation: Excellent for applications demanding superior insulation properties.

Design flexibility: Easily tailored to fit the exact specifications and requirements of any project.

Aesthetic appeal: Available in various colours and finishes to complement different design perspectives.

Industry applications

For further information about Kewell Converters’ extensive range of foam and composite materials, feel free to consult our team of experts.

Get in touch

Aerospace and defense

Utilised for its lightness and strength in everything from aircraft components to protective gear.

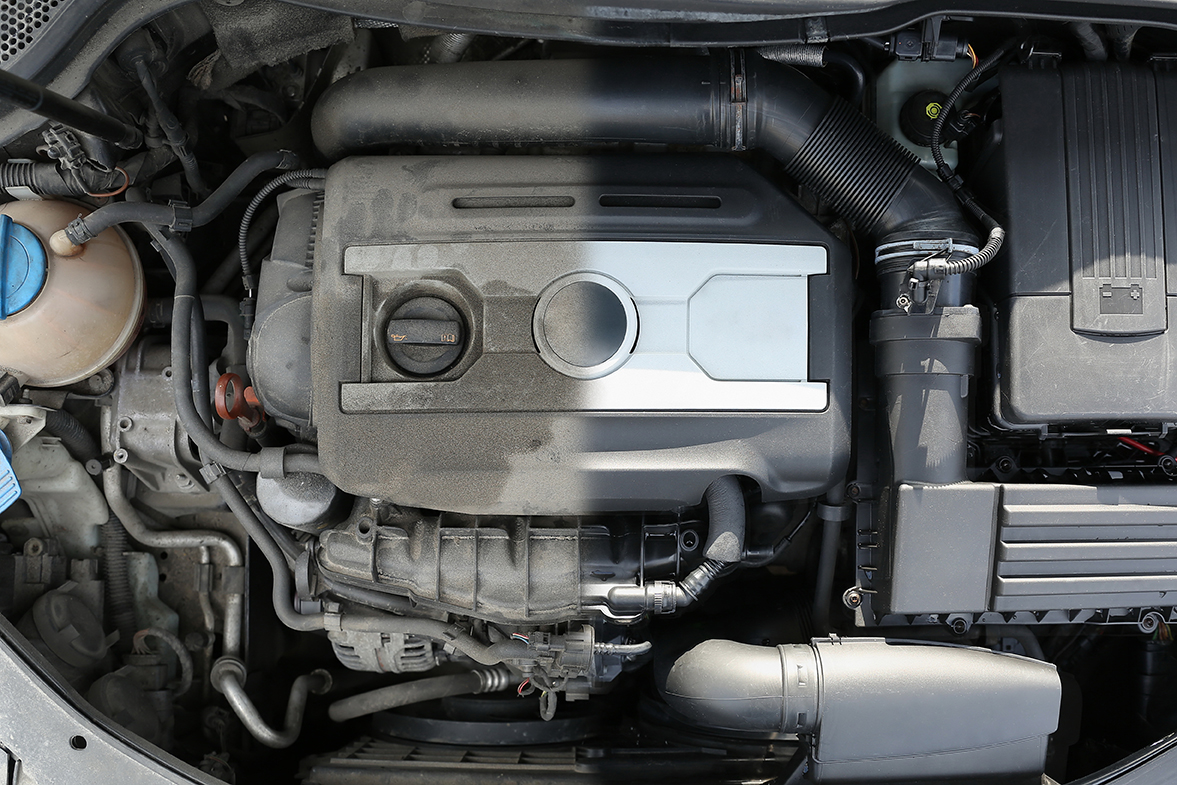

Automotive

Frequently found in car interiors, exteriors, and engine components for enhanced performance and durability.

Renewable energy

Ideal for wind turbines and solar panel components, contributing to efficient energy production.

Construction and infrastructure

Offers structural integrity and longevity in building applications, from bridges to facades.

Marine

Provides crucial benefits in corrosive saltwater environments, such as boats and offshore platforms.

Medical devices

Due to its biocompatibility, it’s frequently used in prosthetics and surgical instruments.

FAQs

Composites stand out for their remarkable strength-to-weight ratio, corrosion resistance, and adaptability, making them ideal for high-performance applications across various industries.

Absolutely, composites are often chosen for medical applications due to their biocompatibility and strength, making them suitable for prosthetics and surgical instruments.

Their exceptional strength and low weight make them ideal for components in wind turbines and solar panels, thus aiding in more efficient energy production.

Yes, their corrosion-resistant properties make them particularly suited for challenging environments, such as saltwater conditions in marine applications.

Composites can be easily tailored to meet specific project needs, available in various shapes, sizes, and even colours to align with different design requirements.