EPDM – rubber foam

Superiority in flexibility and durability

Our EPDM rubber material foam is superior in every way from its flexibility to how long it lasts. Kewell Converters is committed to offering a diverse selection of industrial-grade, closed-cell foams meticulously designed to meet various application needs. This includes product protection, case inserts, and industrial safety components. We provide optimal quality through regular inspections, ensuring our clients receive their orders in impeccable condition.

Request a quote

Distinguished features

Inherent flexibility: EPDM rubber material foams are highly adaptable, facilitating a broad spectrum of applications.

Resilient and lightweight: These closed cell foams are long-lasting and easily transportable due to their lightweight nature.

Waterproof and chemical resistant: Renowned for their imperviousness to water, oil, and ozone, as well as their resilience under fluctuating weather conditions.

Highly customisable: Offered in various formats such as blocks, sheets, and rolls, and can be further customised through punching, milling, or other specified requirements.

Self-wdhesive versions: KÖPP’s KOEPPcell® cellular rubber and other variants are available in a self-adhesive format for ease of application.

Specialised types

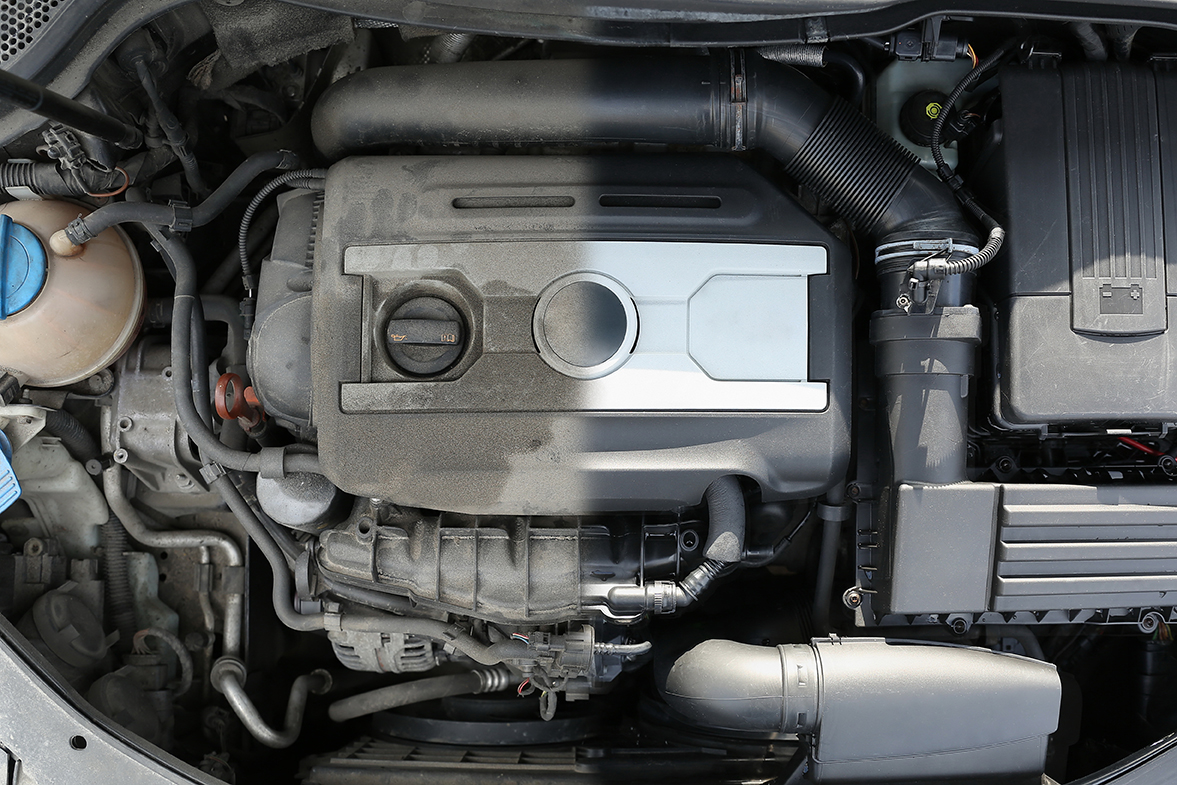

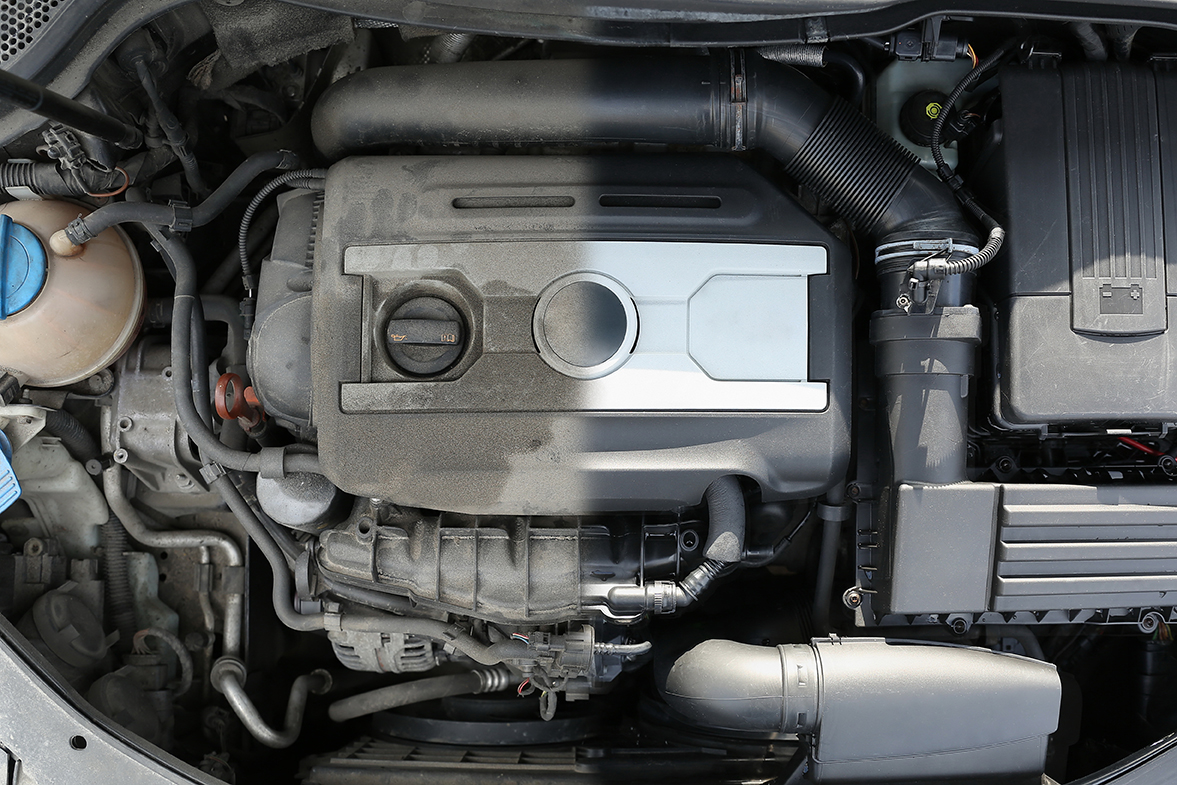

EPDM rubber: This foam-based material offers outstanding resistance to heat, ozone, and steam; commonly utilised for seals in the automotive industry.

CR- chloroprene rubber (Neoprene®): Chemically stable and flexible across a broad temperature range; widely used in gaskets, hoses, and wetsuits.

Polymeric blends:Combines the attributes of various polymers to create materials with unique, tailored characteristics.

Semi-Closed-Cell EPDM: Notable for its excellent recovery properties, ideal for cushioning applications such as car bodies and bumpers.

Flame-Retardant Materials: Materials categorised under UL94 standards, ranging from least to most flame-retardant.

M1/F1 Classified Material: Optimal quality for low emissions and smooth, polished finishes.

Coloured options:Available in various colours to meet aesthetic requirements.

Diverse applications

Our EPDM – rubber foam materials are used in a diverse range of applications across numerous industries from aerospace and shipbuilding to automotive manufacturing.

At Kewell Converters, we strive for excellence in quality and performance, providing material solutions that aren’t just effective but also adhere to the highest industry standards.

Contact us today to find out more about our customised solutions.

View our Industries

Automotive manufacturing

Electronics

Mechanical engineering

Equipment construction

Heating and air conditioning

Household appliances

Aerospace industry

Shipbuilding

FAQs

EPDM – Rubber Foam materials are commonly used across a wide range of industries, including automotive manufacturing, electronics, mechanical engineering, aerospace, and shipbuilding, among others.

Yes, we do. Our flame-retardant materials for EPDM – Rubber Foams adhere to UL94 standards, ranging from the least to most flame-retardant, to suit various application requirements.

Yes, we provide self-adhesive versions of our EPDM – Rubber Foam materials for ease of application.

Yes, we offer coloured material options of our EPDM Rubber Foams to meet specific aesthetic requirements.

Our EPDM – Rubber Foams are characterised by their superior flexibility, resilience, and adaptability. These materials are waterproof, chemical resistant, and can be customised extensively to suit various application needs.

Certainly. The high-quality and versatile nature of our EPDM – Rubber Foams make them ideal materials for demanding applications such as those in the aerospace industry.