Neoprene foam

The benchmark in versatility and performance

Kewell Converters is pleased to present our comprehensive range of closed cell sponge rubber, more commonly known as neoprene foam. This material has carved a niche for itself in various industrial sectors, particularly the automotive industry, due to its exceptional properties.

Request a quote

Key characteristics

Anti-vibration: ideal for damping and vibration control

Compression set: excellent resistance to deformation

Oil resistance: suitable for applications where oil resistance is critical

Sealing properties: acts as an effective sealant

Advantages of neoprene foam

This foam is distinguished by several advantageous properties:

Minimal vibration: effective in damping and vibration control

High energy absorption: ideal for shock absorption applications

Environmental resistance: highly resistant to water, oil, ozone, and adverse weather conditions

Wide temperature range: remains flexible over a broad temperature spectrum

Low flammability: exhibits minimal levels of flammability and smoke release

Industry applications

View our Industries

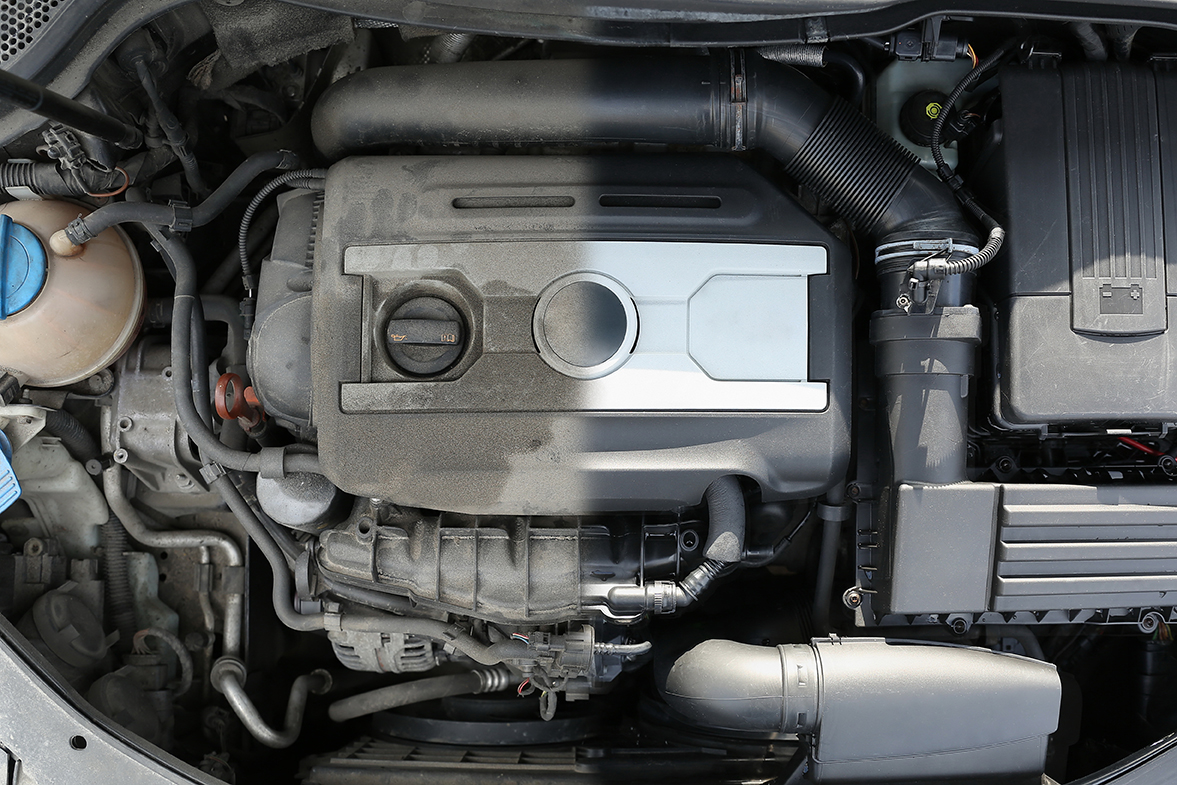

Automotive industry

Electronics

Mechanical engineering

Construction equipment and sheet metal works

HVAC systems

Household appliances and sanitary ware

Aerospace industry

Shipbuilding

FAQs

This foam offers anti-vibration, compression set resistance, oil resistance, and excellent sealing properties.

It is available in sheets, profiles, moldings, strips, punched items, and cut-outs. Self-adhesive options are also available.

Yes, it is resistant to water, oil, ozone, and detrimental weather conditions.

This foam remains flexible and functional over a wide range of temperatures.

It is widely used in automotive, electronics, mechanical engineering, HVAC systems, household appliances, aerospace, and shipbuilding industries among others.

While Neoprene Foam has low levels of flammability, it is essential to specify if you require material that meets specific fire safety standards.