18th March 2025

Kewell Converters and the defence sector: Developing custom military foam solutions

Read more >

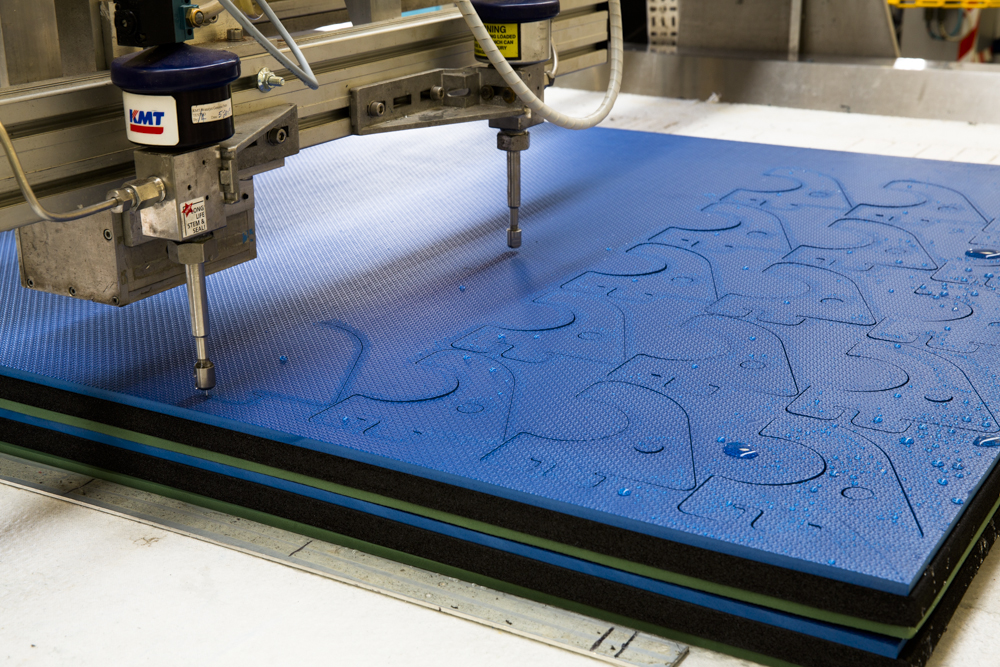

Precision Meets Innovation: Water-Jet Cutting at Kewell Converters

In the realm of manufacturing brilliance, Kewell Converters casts a long shadow, built upon decades of engineering expertise. Today, we’re lifting the veil on the wonders of water jet cutting—a process at the heart of our operations and a testament to our passion for perfection. Our experienced team embraces this advanced technique, delivering consistent and precise results.

Our collaboration with esteemed brands like Axminster Tools and Playforce underscores our capability to marry traditional wisdom with innovation, creating tools and products of exceptional quality.

Understanding the Art of Water Jet Cutting

The precision cutting capabilities of water jet technology brings an astonishing flexibility to material processing. Broadening the window on the types and thicknesses that can be fabricated, and unrivalled by other processes. It’s celebrated for its extraordinary precision — a technique that effortlessly achieves stellar finishes, setting your products apart in the marketplace. We stand as advocates for water jet cutting, utilising it to achieve seamless conjunctions with other manufacturing methods for impressively exact results and occasionally as a standalone finishing process for pure precision.

The Fleet of High-Performance Machines at Kewell Converters

Our commitment and investment to water jet cutting technology spans over two decades, during which we’ve observed the remarkable returns. Consequently, we’ve expanded our machinery, transitioning to three state-of-the-art water-only jet machines and bolstered efficiency and versatility through multiple cutting heads.

Nick Kewell, our Managing Director, advises “This technology affords us sharp, clean edges and a higher-calibre result, enabling the manufacture of components otherwise impossible with conventional press tools. In essence, it’s a merging of quality and excellence within a single, sophisticated piece of machinery.”

Industrious Versatility

Our waterjet technology caters to an extensive range of industries with its versatility.

We use this process a lot for foam inserts and trays that are used in the retail and luxury goods sector. When you use foam as a product protection material and you want to keep the look high end, you can use a water jet to achieve a very high quality finish.

Axminster Tools: Crafting Precision for Excellence

For over five years, Kewell Converters has partnered with Axminster Tools, a UK market leader in tools and machinery distribution renowned for their vast product range of over 14,000 items. Axminster Tools demands nothing but the highest standard of craftsmanship from their suppliers, and our water jet cutting technology plays a pivotal role in meeting their exacting standards.

We utilise water jet cutting in conjunction with other processes to create bespoke foam inserts for Axminster Tools’ products. These inserts are designed to securely store, protect, and present the tools. They’re crafted with precision before being routed to meet specific configurations. The water jets not only allow us to cut a very small through hole, which no other machine process would allow, but we can also cut cold so no heat is involved which could impact the foam and final outcome on such an intricate part. This collaboration is a testament to the potential of marrying water jet cutting with delivering products emblematic of quality and care.

Playforce: Shaping Joyful Learning Experiences

Playforce, with a 15-year history of creating delightful play environments, believes in the power of play for learning, social development, and encouraging physical growth. At Kewell Converters, we’ve harnessed water jet cutting technology to bring Playforce’s imaginative concepts to life.

We’ve engineered foam products such as large ball skills panels and Velcro target sets fashioned from EVA FOAM – a sturdy, closed-cell material perfect for children’s interactive play. Our creations help nurture hand-eye coordination and muscular strength in young learners. These versatile, lightweight segments can be rearranged to foster new challenges and games, making them an adaptable tool for exploration and fun.

Through water jet cutting techniques, we’ve translated our client’s vision into practical and tangible foam products that enrich UK schools and playgroups. The result is a unique blend of expert design meeting superior manufacturing, driven by Kewell Converters’ commitment to advanced material processing.

Commitment to Craftsmanship

Choosing Kewell Converters means partnering with decades of unparalleled waterjet cutting expertise. It’s our dedicated team that sets us apart—craftsmen and engineers whose careers are a testimony to their skills and passion for this technique. We’re not just employing technology; we’re pushing the boundaries of what’s possible.

Elevate your manufacturing process with the meticulous precision of water-jet cutting provided by us at Kewell Converters. When it comes to transcending traditional limitations and crafting the future meticulously, experience the art of cutting as it should be—crafted by skilled hands and framed by a commitment to excellence.

Connect with Kewell Converters to discuss how our water-jet cutting services can sharpen the edge of your production. Here’s to forging ahead with precision-led manufacturing – today and beyond. Get in touch with us and see how true precision comes to life.

Read more from our blog including All You Need to Know About Water Jet Cutting and Reflecting on Engineering’s Future – Celebrate World Engineering Day with Nick Kewell

18th March 2025

Read more >

17th March 2025

Read more >

6th March 2025

Read more >